Engineering final project:

April-May, 2022

Background:

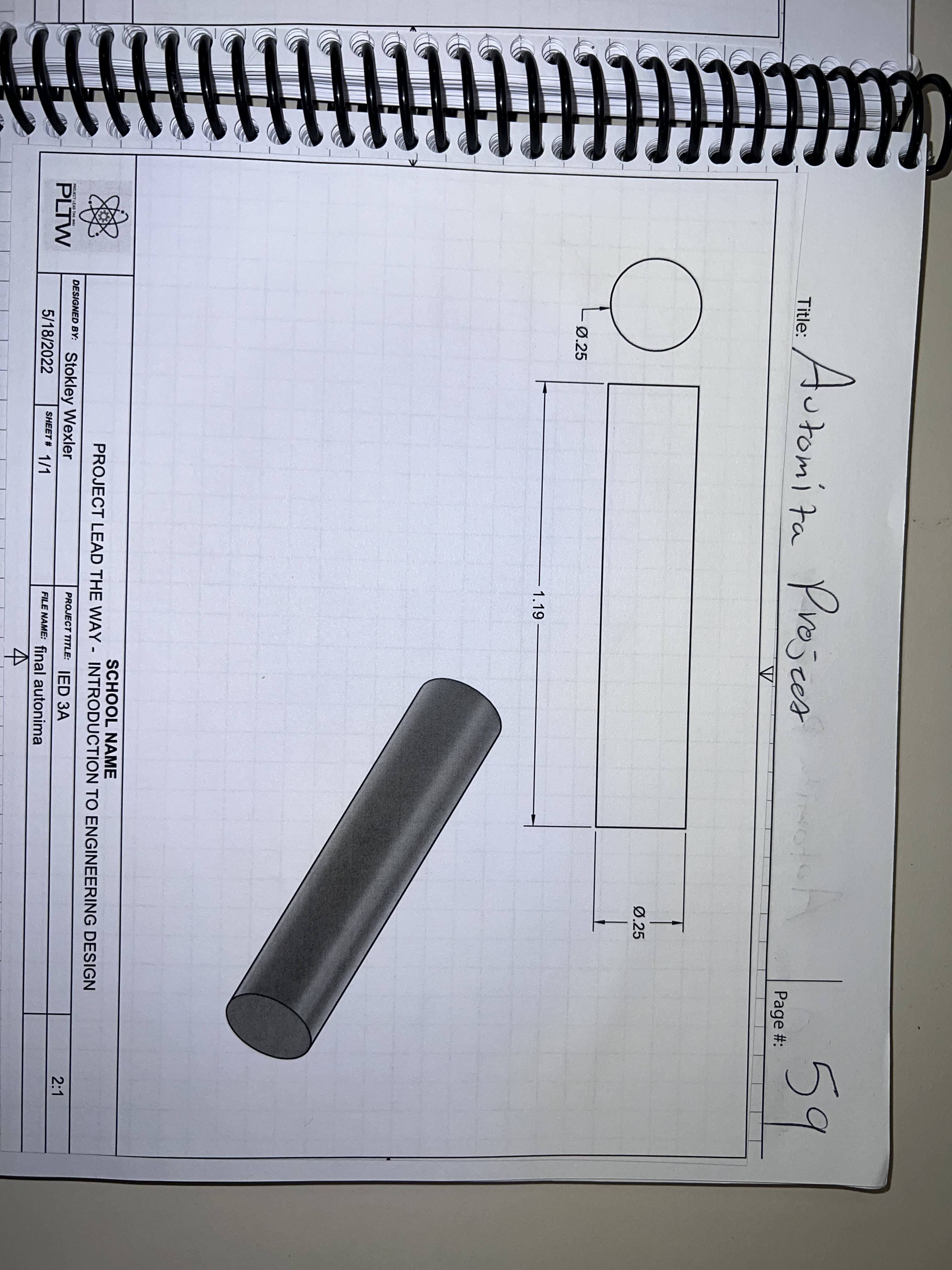

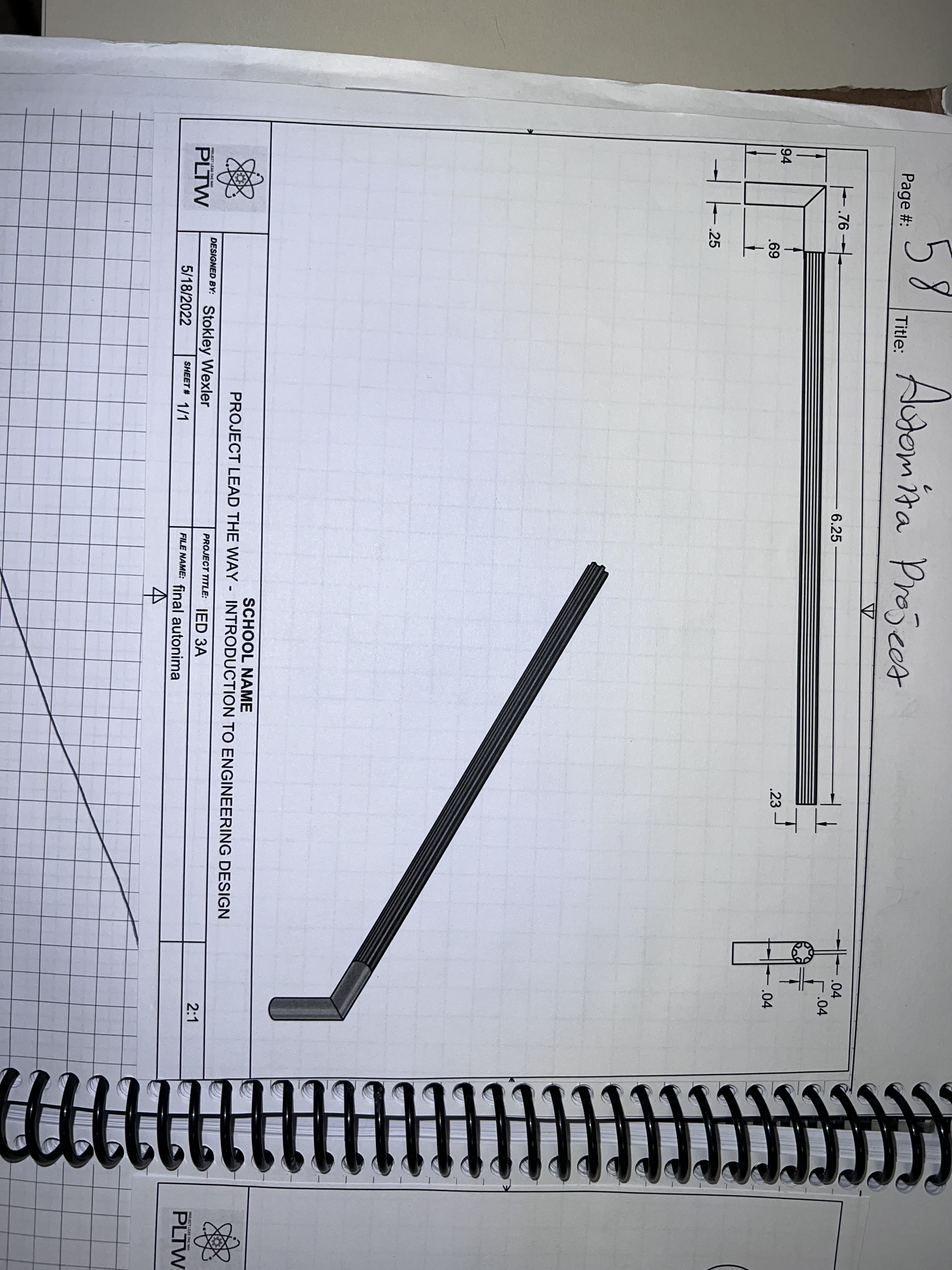

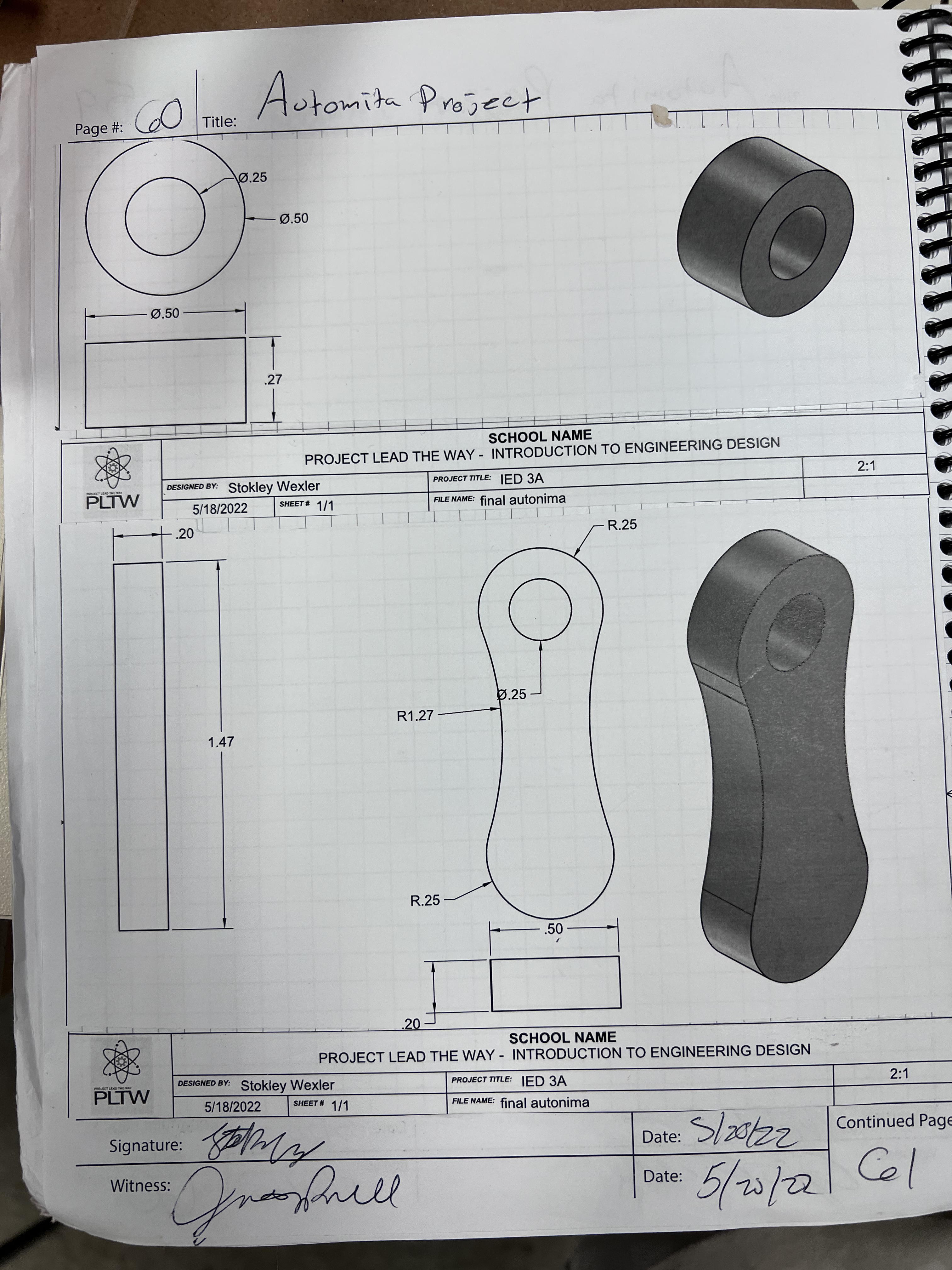

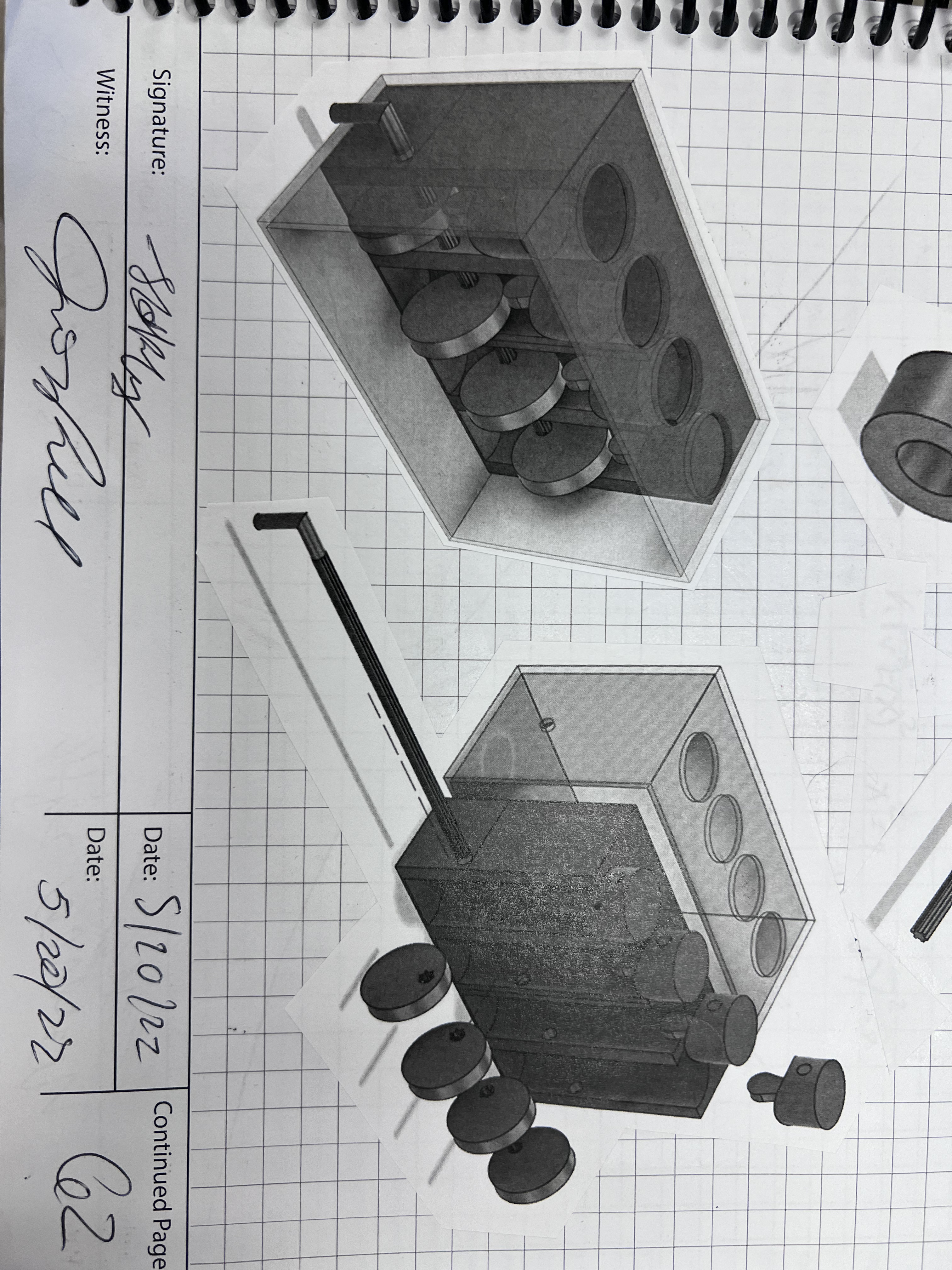

I took an engineering class my freshman year of high school. The final project was open ended, where we had some creative fredom. The constrints were that each project had to use cams, and fit in a 8x4x6 inch box. I chose to model my design after a inline four cylinder engine as i like car culture.

Design:

This project was more complicated than inticipated. This is due to the documentation aspect that was key in my class. We had to keep track of our progress through a gant chart and an engineering notebook, and that proved to be challenging for me. Stopping what i am doing and documenting it is not something that comes to me naturally and although it was difficult for me to do at first, i eventaully got used to it and it has proved to be helpful.

I also made it so that the positoion of the cams was adjustable, so the firing sequance could be adjusted. i did this by making splines in the shaft that interacted with splines cut out of the cams so that they could be rotated in different ways which allowed the firing sequance to be altered.

Post-project thoughts:

Reflecting on this project, i think i did pretty well given it was over a year ago and i didnt have as much exsperiance designing models and working with 3d printers.

As of right now, i dont think i would've done anything differently as i went above and beyond the scope of this project and succsessfuly brought my vision to life.

Skills:

Fusion 360

documentation

3d printing

Pictures: